Production systems in business. All You Need to Know About the Production System and Its Types 2022-10-24

Production systems in business

Rating:

6,4/10

1899

reviews

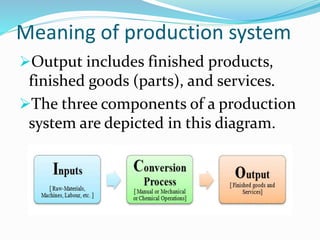

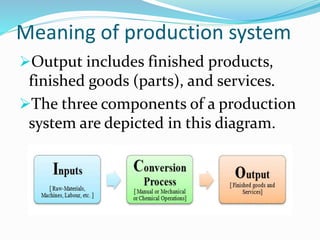

A production system is a set of interrelated processes that work together to produce goods or services. In business, production systems are critical to the efficient operation of an organization and the creation of value for customers.

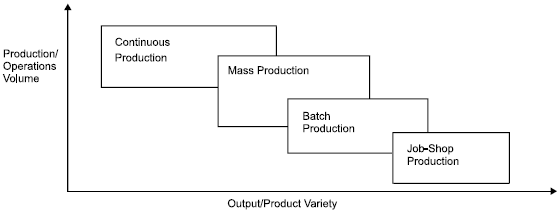

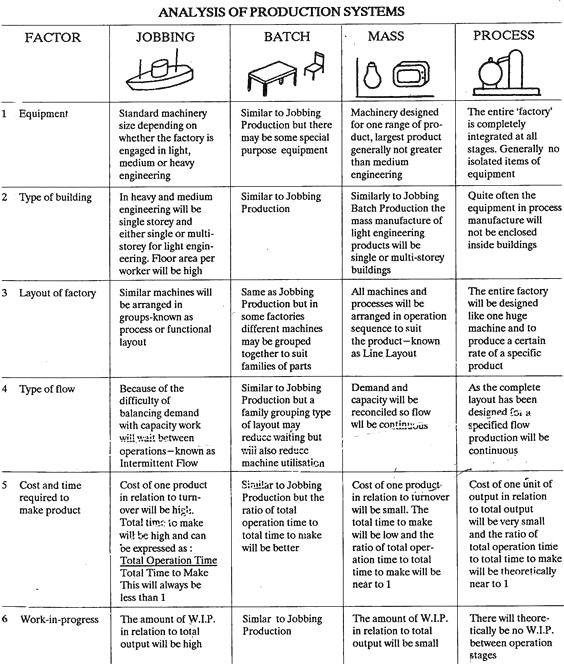

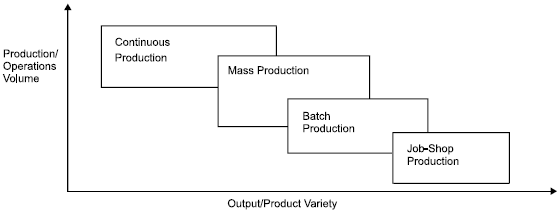

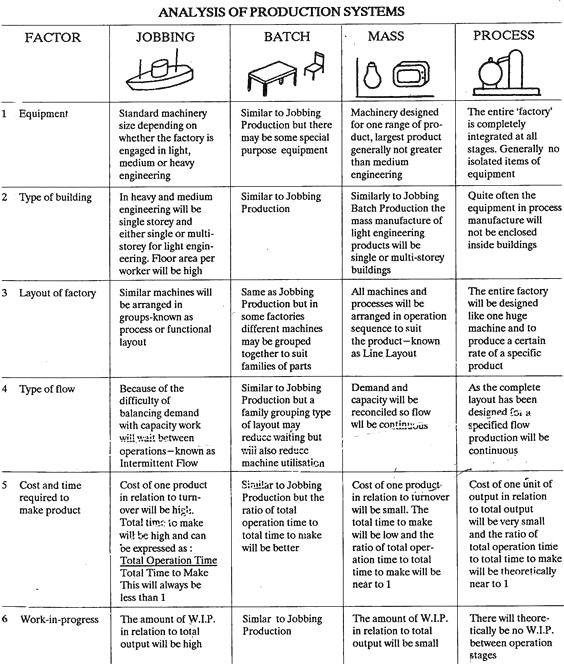

There are several types of production systems, each with its own characteristics and suitable for different kinds of products and industries.

One of the most common production systems is the assembly line, which is used in mass production. This system involves dividing the production process into a series of tasks, each of which is performed by a specialized worker. The worker completes his or her task and then passes the product along to the next worker, who performs the next task. This process continues until the product is complete. The assembly line allows for a high degree of specialization and efficiency, but it can also be inflexible and may not be suitable for products that require a lot of customization.

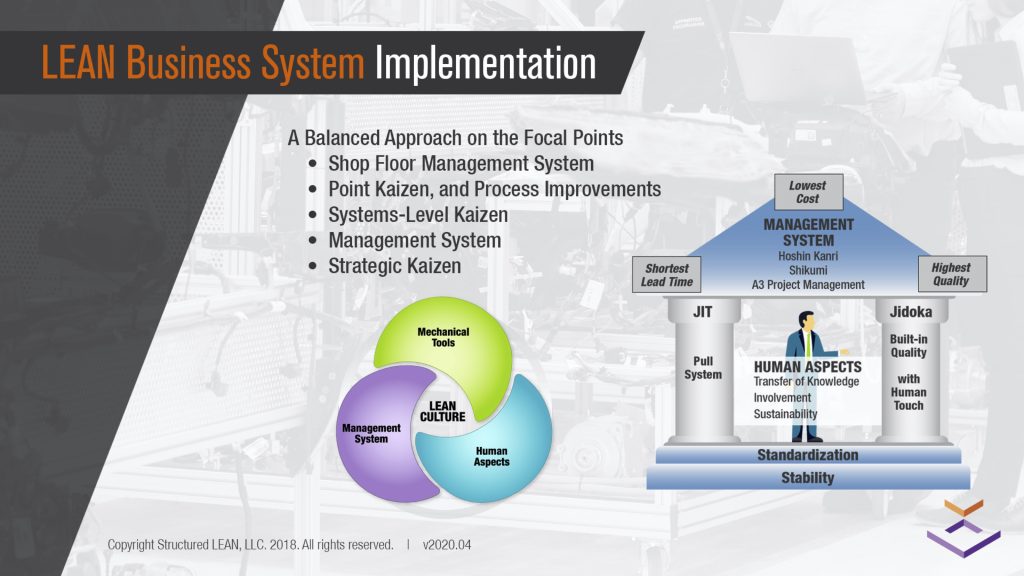

Another common production system is the just-in-time (JIT) system, which is used to minimize waste and reduce inventory costs. In a JIT system, raw materials and components are delivered to the production facility as they are needed, rather than being stored in inventory. This reduces the need for storage space and allows the organization to respond quickly to changes in demand. However, the JIT system requires careful planning and coordination to ensure that raw materials and components are delivered on time.

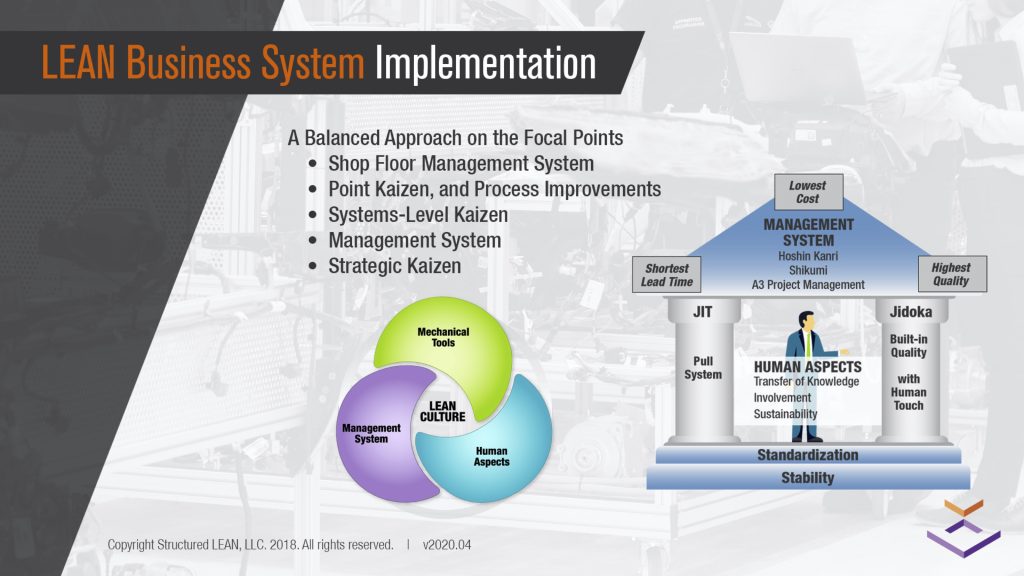

A third type of production system is the lean system, which is focused on maximizing value and minimizing waste. In a lean system, unnecessary steps or activities in the production process are eliminated, and the remaining steps are optimized to increase efficiency. This may involve streamlining the production process, improving communication between workers, and reducing the amount of inventory. Lean systems can be highly efficient and flexible, but they require a high degree of collaboration and continuous improvement.

In addition to these types of production systems, there are also hybrid systems that combine elements of different approaches. For example, an organization might use an assembly line for some tasks and a JIT system for others.

Ultimately, the choice of production system will depend on the specific needs and goals of the organization, as well as the nature of the product or service being produced. By carefully considering the trade-offs between efficiency, flexibility, and other factors, businesses can select the production system that is best suited to their needs and help ensure their long-term success.

Push and Pull Production Systems

Decisions are made regarding the quantity and quality of goods and services as well as on the place of production. An effective planning and control on production parameters to achieve or create value for customers is called production management. Larger companies will normally have a separate information systems department Using Information Systems to Achieve Competitive Advantage Firms with a competitive advantage over others, typically have access to special resources that others do not or are have special competencies that enable them to use resources more efficiently, or in ways that their competitors find difficult to imitate. Generally, production processes may share similar factors of production with land, labor, capital, and technology. .

Next

What Is Business Information Systems?

Discrete manufacturing is a term that refers to any type of assembly process that results in the construction of distinct, finished products, made up of any number of individual parts or components. You can check out the following production systems: 1. Production by assembly: Car production and computer are example of production by assembly. They also need to know about trends. These systems help suppliers, purchasing firms, distributors and logistics companies share information about orders, production, inventory levels, and delivery of products and services so that they can source, produce and deliver goods and services more efficiently. There are four types of production systems based on their objectives: 1.

Next

Types of Production Systems

Say one dress is specifically designed for a celebrity for a particular award show, on-demand, with a choice of colour and pattern, and customised to the event's theme. MIS systems tend to have an internal orientation where the primary sources of information are internal and the users are normally members of the organisation. ADVERTISEMENTS: Then several operations, such as sawing, nailing, sanding and painting can occur through which inputs are converted into such outputs as chairs, tables, etc. This allows businesses to fulfill smaller batches of custom products, however, can be difficult to automate depending on the level of personalization. DSS use data from TPS and also MIS.

Next

Manufacturing Systems: 6 Common Systems & Processes Used in…

It measures the resources used in production against the final products. Examples of service industries which use production concepts are hospitals, railroads, airlines, supermarkets, automobile repair shops, etc. Intranets and Extranets are discussed in detail in Chapter 5. Business processes also refer to the ways in which organisations coordinate and organise activities, information and knowledge to produce their products or services. Competitive advantage can be turned into higher profits for the company. Allan started with a marketing manager two hours a day.

Next

Production system

By automating, delegating, and systemizing your business activities and business functions, you gain leverage, which is the key to creating and scaling a high growth organization. To that end, a What Is a Business Information Systems Degree? Information System Strategies for dealing with Competitive Forces Michael Porter developed a number of generic strategies that can be used by companies to deal with competitive forces. They can facilitate different firms working collaboratively on product design, marketing and production. Production management and operations management both are very essential in meeting objective of an organization. In short, everything which is done to produce goods and services or to achieve the production objective is called production system. Because of a lack of business systems. Introduction The very essence of any business is to cater needs of customer by providing services and goods, and in process create value for customers and solve their problems.

Next

Production Process: Definition, Types & Examples

The extractive process refers to the activities done in getting the raw materials from their source. TPS are operational-level systems that gather transaction data. If you want to double revenue, you need to double the hours you work. The concept of production system is applicable to both production of components and production of services as well. It makes use of special purpose machines and produces standardized items in large quantities.

Next

All You Need to Know About the Production System and Its Types

Degree programs may not be available in all U. Hence, we can say that, production system is a union or combination of its three main components viz. So what is the gold standard? Production and operations management talks about applying business organization and management concepts in creation of goods and services. They can take the media pitching business system, read it, and hit the ground running. Production process definition The production process is defined as the process in which the factors of production, i. Have you ever thought about how such large quantities are supplied in the market where demands are in the tonnes? Process-Based Production System The first is the process-based production system, divided into the continuous process and intermittent process types.

Next

Production System: Concept and Models

The factors of production are explained in detail below: Capital Capital includes the amount invested in the process of production. Huge systems are often a collection assembly of smaller sub-systems. Relationship between Systems The various forms of systems in the organisation exchange data with each another See Figure 2. Data input to the system in manufacturing must be made available to sales, accounting and logistics. Supply chain management systems are a form of inter-organisational system because they automate the flow of information across organisational boundaries. This type of system is characterized by its use of automated equipment and computer-controlled robots.

Next

Types and Functions of Information Systems Used in Business

The MTO system is a production system that runs when a producer has received an order. Systems allow you to deliver a consistent experience, which is super powerful. What is Job Shop Manufacturing Mass Customization Job shop manufacturing, also known as mass customization, is a process that combines the personalization of custom products, increasingly popular across many consumer goods, with the low costs and production efficiency found in traditional production systems. That's where Schlumberger production expertise, systems, and tools come in. What is a Manufacturing System? For example, Coca-Cola may have custom 500ml bottles in glass produced in larger quantities according to need. Who will film an instructional video? Many business processes are linked to a specific functional area, such as sales and marketing, while others cross many different functional areas and will also require coordination across departments. In addition, KNIC is also supported by facilities such as premium electricity, natural gas, and fast internet connections to support the performance of manufacturing companies.

Next

Types of Production System in Operation Management (OM)

Her medical background also has given her an edge when it comes to writing medical and health-related content. This graphically shows what emojis to include, how to write a question that draws attention, the position of hashtags, etc. Follow-up measures the actual versus the expected productions. Here the inputs and conversion process are continuously adjusted and changed according to the design, shape, size, and quantity of is make the flow of material and resources intermittent i. Intermittent Manufacturing System Also known as What is the Manufacturing Process? Types of Manufacturing Systems There are various manufacturing systems, each with its purpose and importance. Production process flow chart The production process goes through various stages, which can be understood with the help of the flow chart. Scheduling is prepared for each job.

Next