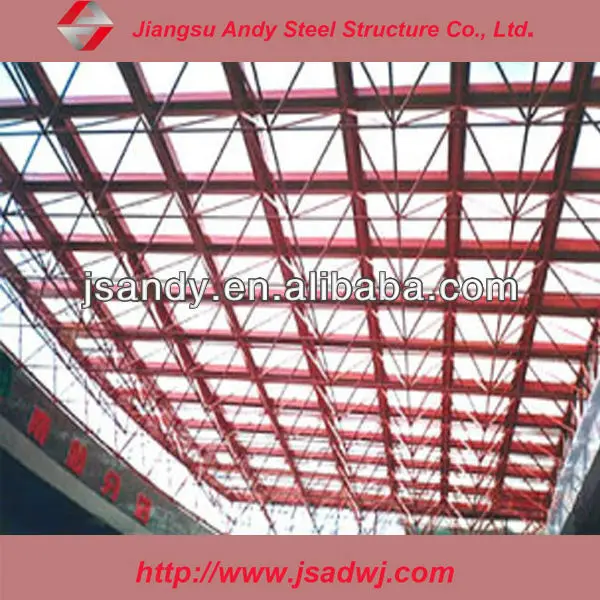

A lightweight truss is a structural element commonly used in the construction industry to provide support for various types of loads. Trusses are designed to transfer loads through a network of triangles, which helps to distribute the weight evenly and reduce the overall stress on individual members. This makes trusses an efficient and effective solution for a wide range of applications, including bridges, roofs, towers, and other structures.

There are many different types of trusses, including rigid trusses, pin-jointed trusses, and space trusses. Lightweight trusses, in particular, are designed to be as lightweight as possible while still maintaining their structural integrity. This is achieved by using materials with a high strength-to-weight ratio, such as aluminum or carbon fiber, as well as optimizing the design of the truss to minimize the amount of material needed.

One of the main advantages of lightweight trusses is their ease of transportation and installation. Since they are lighter than traditional trusses, they can be easily moved and assembled on site, which can save time and labor costs. In addition, lightweight trusses often require less foundation support, which can further reduce construction costs.

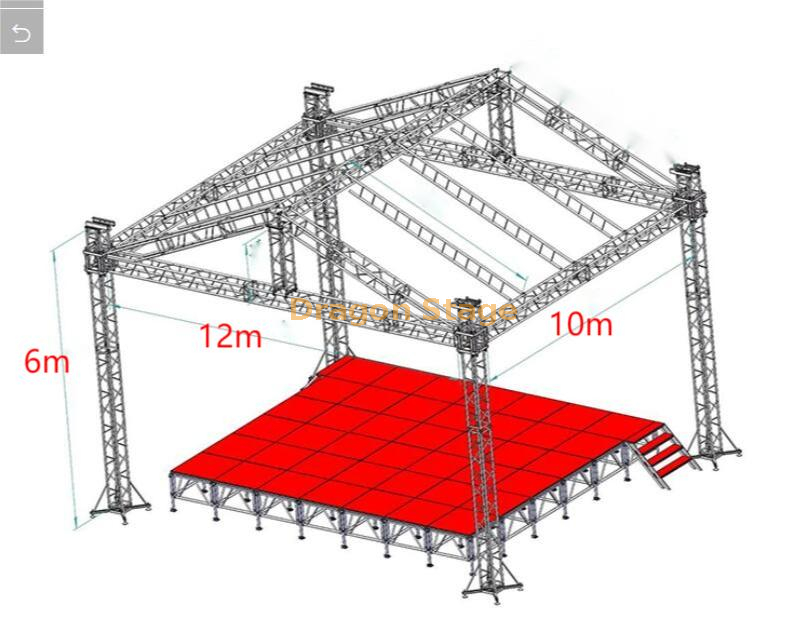

Another benefit of lightweight trusses is their versatility. They can be used in a wide range of applications, including temporary structures, such as event tents and stages, as well as permanent structures, like bridges and buildings. They can also be easily customized to meet specific design requirements and can be incorporated into a variety of architectural styles.

Despite their many advantages, lightweight trusses do have some limitations. They may not be suitable for very heavy loads or high-stress applications, and they may not have the same level of durability as heavier trusses. However, with proper design and maintenance, lightweight trusses can provide a cost-effective and efficient solution for a wide range of structural needs.

In conclusion, lightweight trusses are a useful and versatile structural element that offer many benefits, including ease of transportation and installation, versatility, and cost-effectiveness. While they may not be suitable for all applications, they can provide a valuable solution for a wide range of needs in the construction industry.