Production planning and control (PPC) is a critical function in the operation of any manufacturing or production organization. It involves the planning, coordination, and control of all activities related to the production of goods and services. PPC is essential for ensuring that production meets customer demand, is efficient, and meets quality standards.

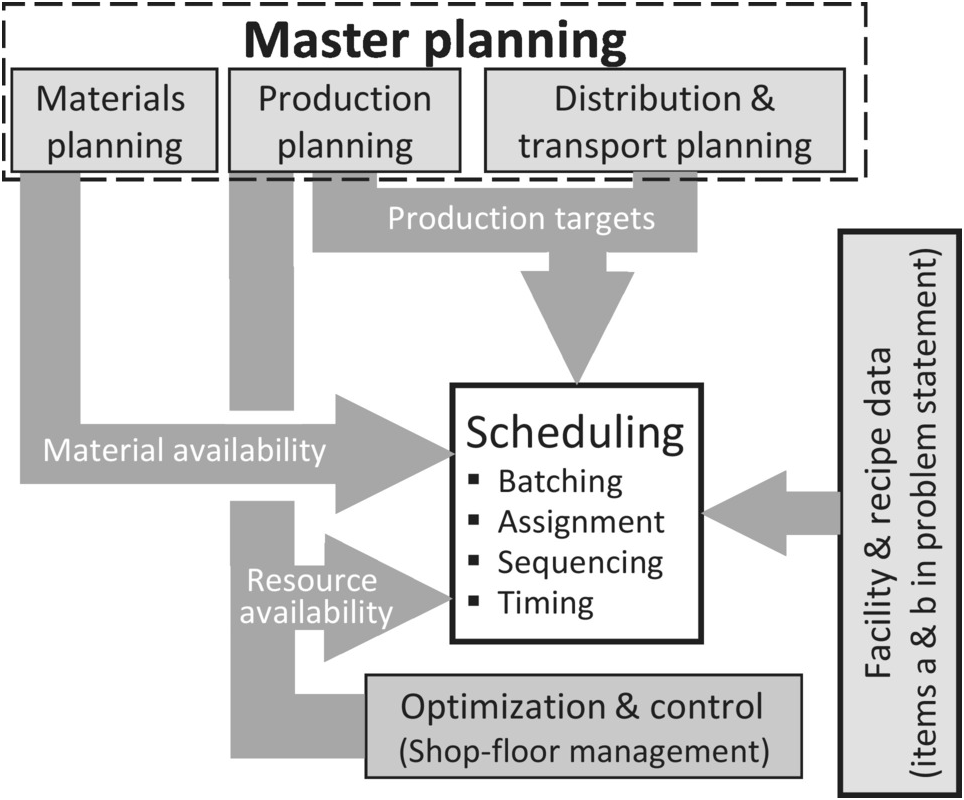

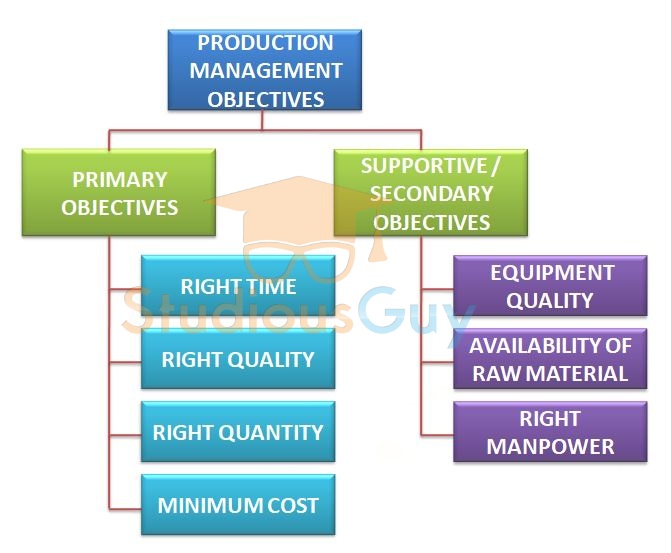

One of the primary functions of PPC is to develop and maintain a production schedule. This involves forecasting demand for products and determining the resources, materials, and equipment needed to meet that demand. PPC must also consider factors such as lead times, delivery schedules, and the availability of raw materials and components. By developing a comprehensive production schedule, PPC can ensure that production meets customer demand in a timely and efficient manner.

Another key function of PPC is to coordinate the flow of materials and information throughout the production process. This involves ensuring that materials are available when needed and that there are no bottlenecks or delays in the production process. PPC must also coordinate the movement of finished goods from the production area to storage or distribution centers, as well as managing the transportation of goods to customers.

In addition to coordinating the flow of materials and information, PPC is responsible for controlling the production process. This includes monitoring and adjusting production levels to meet demand, ensuring that quality standards are met, and identifying and addressing any issues that may arise during the production process. PPC must also track and record production data, including quantities produced, production costs, and other metrics, to help identify areas for improvement and optimize the production process.

Finally, PPC plays a crucial role in managing and optimizing resources, including labor, materials, and equipment. This involves identifying the most efficient and cost-effective methods of production, as well as ensuring that resources are used efficiently and effectively. PPC must also consider factors such as maintenance and repair schedules, as well as the availability and allocation of resources.

In summary, production planning and control is a vital function in any manufacturing or production organization. It involves developing and maintaining a production schedule, coordinating the flow of materials and information, controlling the production process, and managing and optimizing resources. By effectively managing these functions, PPC helps ensure that production meets customer demand, is efficient, and meets quality standards.

What Are the Steps in Production Planning and Control?

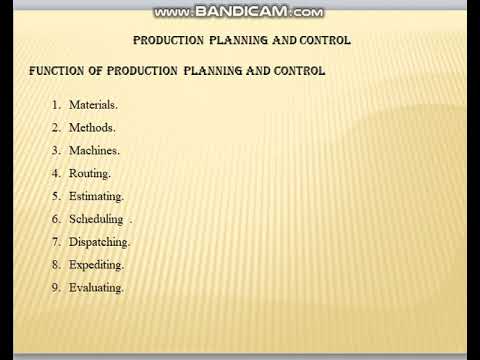

The first attempts to control the variables in the production system, while the second attempts to maximize output. Routing It is the method of determining the chain of operations to be carried out in the production line to complete the assembling of garments. The end goal is the most efficient and profitable production possible. Keeping enough stock on hand to fulfill demand, but not so much that it becomes expensive to store, is a key part of production planning and control. Similarly, delays in delivery can cause a poor customer experience. Production Planning and Control PPC The start of production planning and control is kick-started after you, the Think of Production Planning and Control In the same way, you have your production management system design for your production planning phase, where you plan the workflow, the resources, the time, the effort, and the cost, and the production control measures will ensure that they are all monitored and checked at all times, for adjustments and adherence. Machine and manpower: Methods of garment manufacturing have to be related to the available production facilities coupled with labor and a detail study of equipment replacement policy.

Functions of Production Planning and Control (PPC) department in Textile Industry

Inspection Inspection bouts and audits should be conducted to ensure everything under the productions scanner adhered to the proper quality standards. What are the product tolerances? These different errors and deviations are then studied and analyzed only to provide suitable and remedial actions to avoid the reoccurrence, for smooth functioning. They decide suggest how much order they should accept according to their production capacity, that is, allocating of total capacity or deciding how much capacity to be used for an order out of the total factory capacity. Scheduling This stage is to determine the time required around the process, machines, and resource to complete a particular task, activity, or step. The success of this step depends on the communication, Data and information gathering and analysis. Machines and Equipment: This function is related with the detailed analysis of available production facilities, equipment down time, maintenance policy procedure and schedules.

Functions of Production Planning and Control (PPC) Department in Apparel Manufacturing

In large manufacturing operations, production planning and control are vital to maintaining the highest levels of product quality. Planning will involve performing tasks at the right time and under the right circumstance and environment. Or is it something that needs to get adjusted? The production planning functions include the following: 1. It helps understand the production process better and how an organization can get more out of every stage. When they met with unprecedented demand for packaged, ready-to-eat foods during the Covid-19 pandemic, they found themselves unprepared. For instance, if schedules are not met, is it from an unusual circumstance? It authorises the start of Production activities by releasing materials, components, tools, fixtures and instruction sheets to the operator.

.jpg)