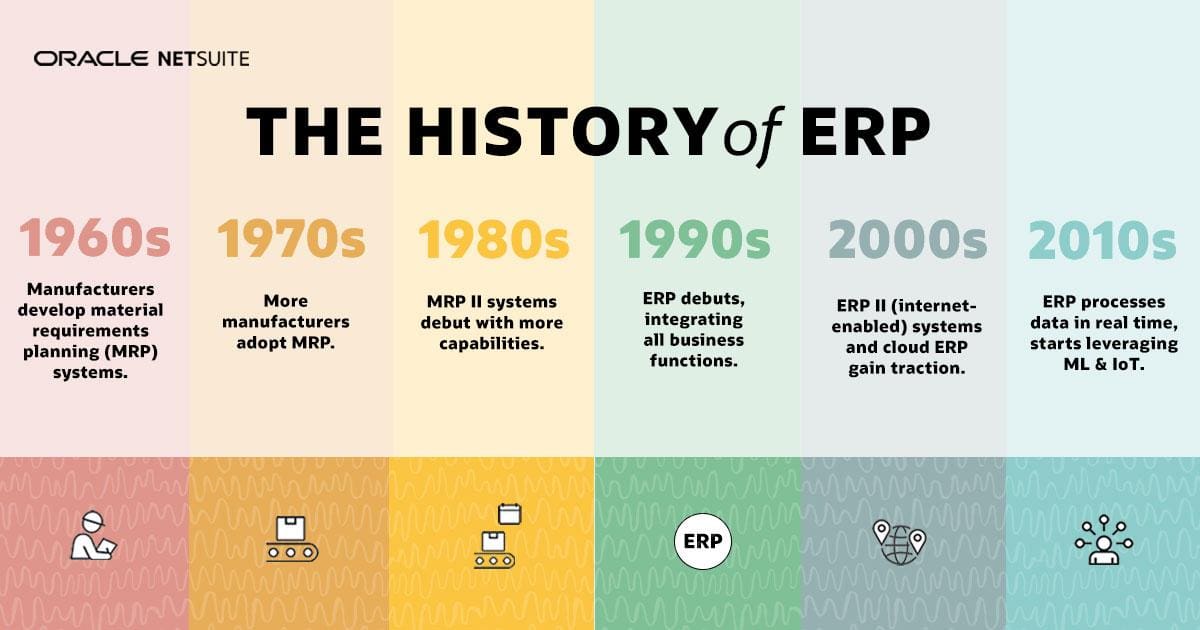

Enterprise resource planning (ERP) and manufacturing resource planning (MRP) systems are software platforms that help organizations manage and optimize various business processes and operations. Both ERP and MRP systems provide a centralized database and a set of tools and modules that enable organizations to automate and streamline their operations, improve efficiency and productivity, and make better informed decisions.

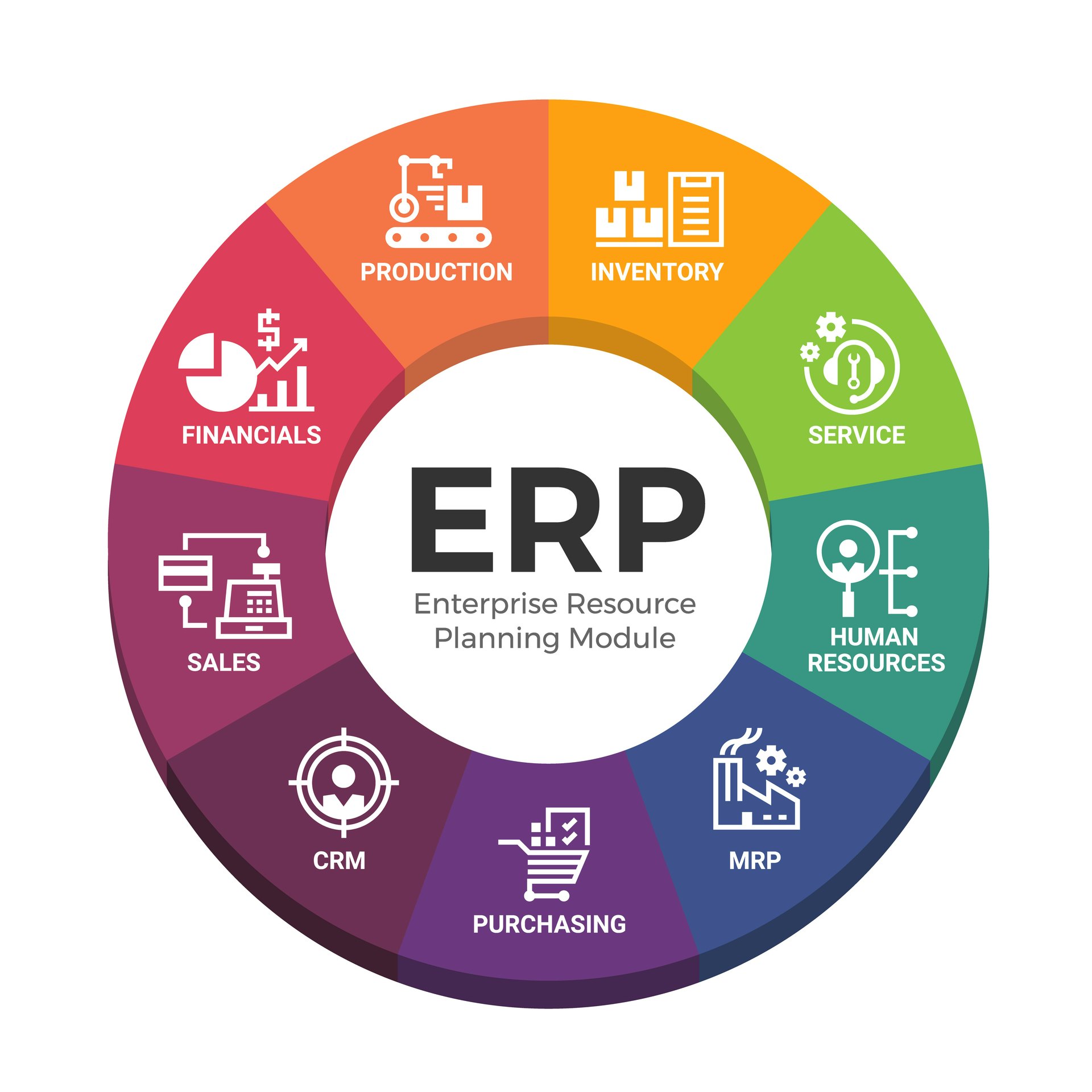

ERP systems are designed to support and integrate a wide range of business functions and processes, such as finance, accounting, HR, marketing, sales, supply chain management, and customer relationship management. ERP systems provide a single, unified platform for managing and organizing all the data and information related to these functions, and enable organizations to gain a comprehensive and real-time view of their operations. ERP systems also offer tools and modules for automating and optimizing various processes, such as financial transactions, order processing, inventory management, and HR management.

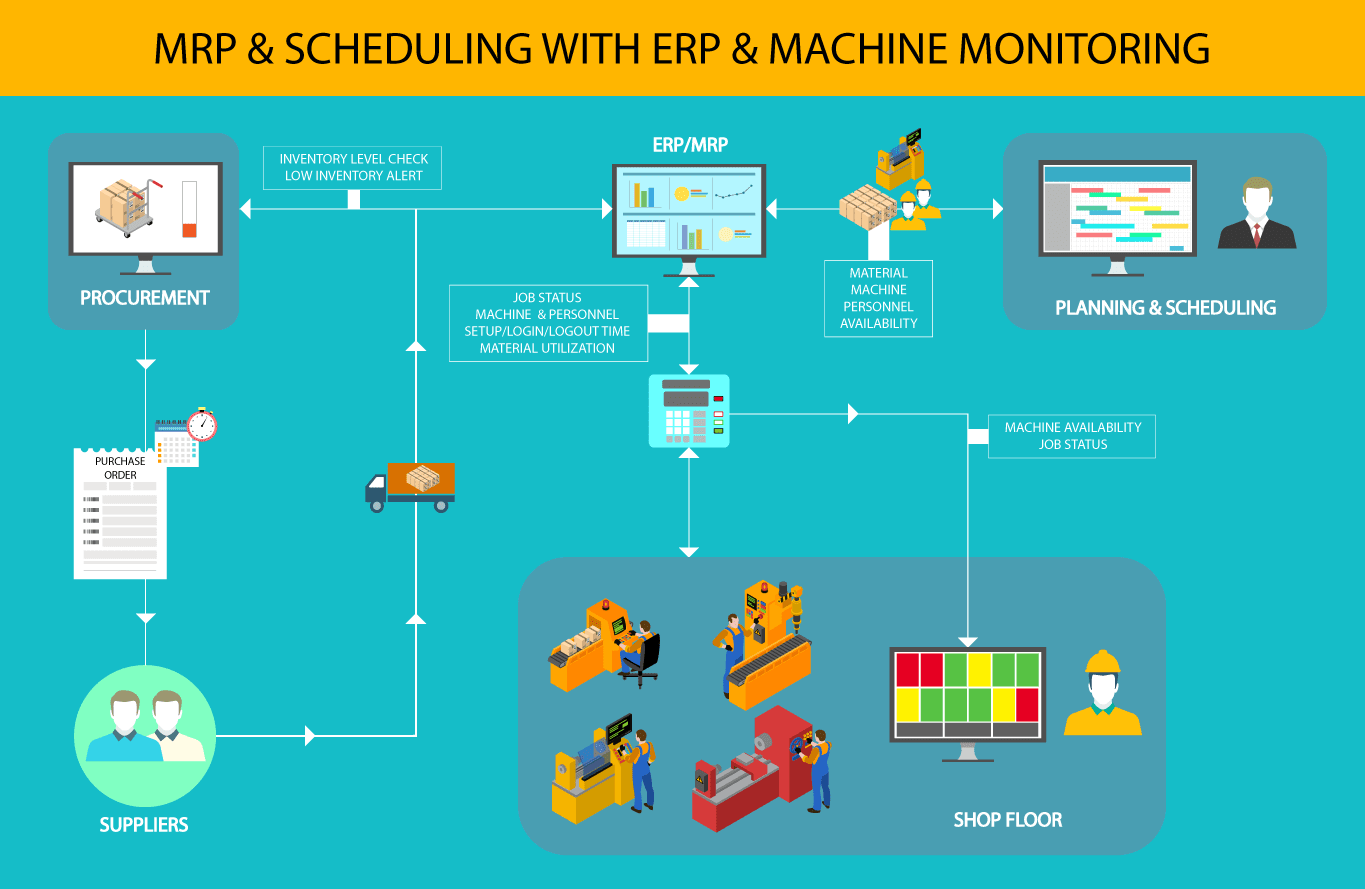

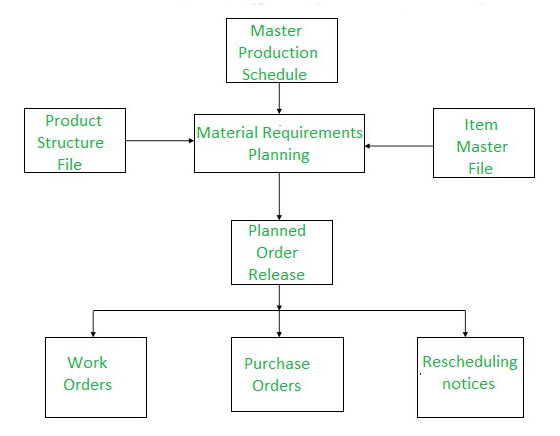

MRP systems, on the other hand, are specifically designed for manufacturing organizations. They help manufacturers plan and optimize their production processes, by providing tools and modules for managing and tracking raw materials, inventory, and finished goods. MRP systems also enable manufacturers to plan and schedule their production activities, and to optimize the use of their resources, such as machines, labor, and materials.

One of the main advantages of ERP and MRP systems is their ability to provide a single, unified platform for managing and organizing data and information. This enables organizations to eliminate silos and reduce the complexity of their operations, and to make better informed decisions based on real-time data and insights. ERP and MRP systems also enable organizations to automate and optimize various processes, which can help improve efficiency, reduce errors and waste, and lower costs.

However, implementing and using ERP and MRP systems can be complex and expensive, and requires a significant investment of time and resources. Organizations need to carefully assess their needs and goals, and choose a system that meets their specific requirements. They also need to ensure that they have the necessary infrastructure, skills, and resources to implement and maintain the system, and to train their employees on how to use it effectively.

In conclusion, ERP and MRP systems are powerful tools that can help organizations manage and optimize their operations and processes, and make better informed decisions. While they can be complex and expensive to implement and use, they offer many benefits that can help organizations improve efficiency, productivity, and competitiveness.