Bending stress is a type of mechanical stress that occurs when a beam is subjected to a load that causes it to bend. This type of stress is important to consider in the design and analysis of structures such as bridges, buildings, and other structures that are subjected to bending loads.

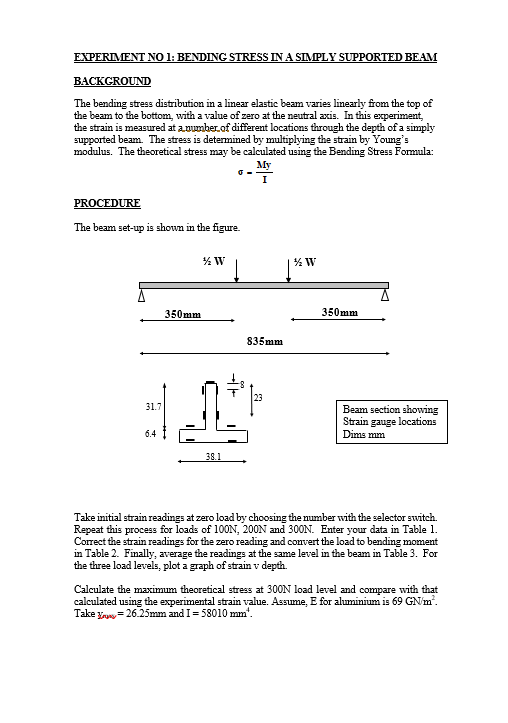

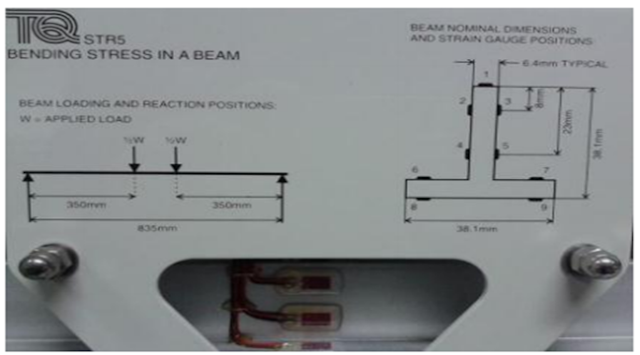

In a beam bending experiment, the goal is usually to determine the bending stress distribution along the length of the beam, as well as the overall bending strength of the beam. To do this, a load is applied to the beam in a controlled manner, and the resulting deflection of the beam is measured. From this data, the bending stress in the beam can be calculated using a variety of techniques, such as the beam bending formula or finite element analysis.

There are several factors that can affect the bending stress in a beam, including the type and size of the beam, the load applied to the beam, and the material properties of the beam. For example, a beam made of a stronger, stiffer material such as steel will be able to withstand a higher bending stress than a beam made of a weaker, more flexible material such as wood. Similarly, a larger beam will generally be able to withstand a higher bending stress than a smaller beam, due to its increased cross-sectional area and moment of inertia.

In order to accurately measure the bending stress in a beam, it is important to carefully control the load applied to the beam and accurately measure the resulting deflection. This can be done using a variety of instruments, such as load cells, strain gauges, or displacement sensors. The data collected from these instruments can then be used to calculate the bending stress in the beam using the appropriate equations and techniques.

Overall, the bending stress in a beam is an important factor to consider in the design and analysis of structures, as it determines the overall strength and stability of the structure under load. By carefully measuring and analyzing the bending stress in a beam, engineers and designers can ensure that the structures they create are safe and reliable.