A lean supply chain is a business model that aims to reduce waste and increase efficiency in the production and distribution of goods and services. It focuses on maximizing value for customers by streamlining processes and eliminating non-value-adding activities. While lean supply chains offer numerous benefits, they also have their own set of challenges and limitations.

One of the main advantages of a lean supply chain is cost savings. By streamlining processes and eliminating waste, companies can significantly reduce their operating costs and pass on the savings to customers in the form of lower prices. Lean supply chains also tend to be more responsive and flexible, as they are designed to quickly adapt to changes in demand and market conditions. This allows companies to respond more effectively to customer needs and stay ahead of the competition.

Another benefit of lean supply chains is improved quality. By focusing on eliminating waste and streamlining processes, companies can reduce the risk of errors and defects, leading to higher quality products and services. This, in turn, can help to build customer trust and loyalty.

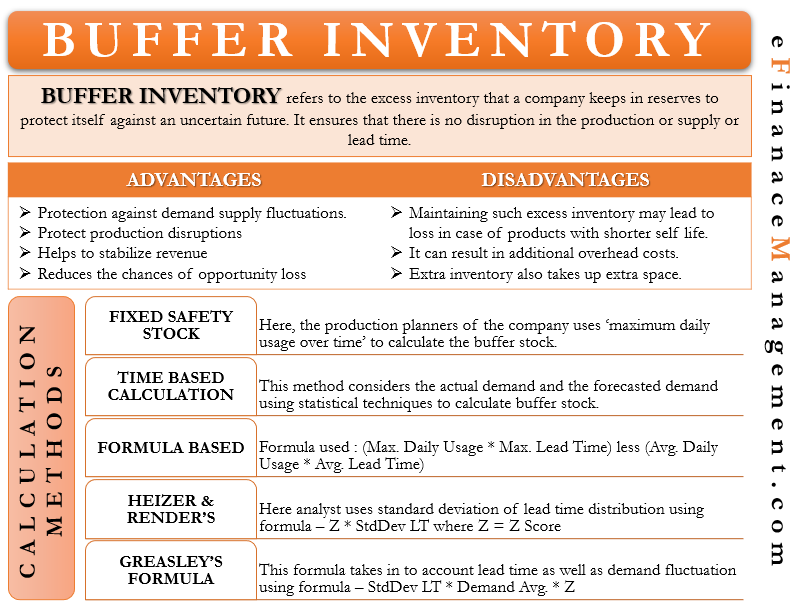

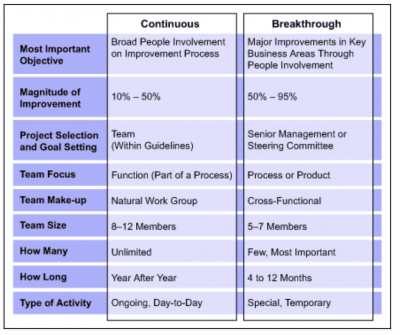

However, lean supply chains also have their disadvantages. One of the main challenges is the need for constant improvement and innovation. Lean supply chains require ongoing efforts to identify and eliminate waste and inefficiencies, which can be a time-consuming and resource-intensive process. Additionally, lean supply chains rely heavily on just-in-time (JIT) delivery, which means that they do not keep large inventories of raw materials or finished goods. While this can help to reduce waste and costs, it also means that companies may be more vulnerable to disruptions in the supply chain. If there are delays in delivery or unexpected demand spikes, it can be difficult for companies to quickly ramp up production and meet customer needs.

Another potential disadvantage of lean supply chains is that they may not be suitable for all types of businesses. While they are well-suited to fast-moving consumer goods and other industries with high-volume, low-variety products, they may not be as effective in industries with complex, customized products or long lead times. In these cases, traditional supply chain models may be more suitable.

In conclusion, lean supply chains offer numerous benefits, including cost savings, improved quality, and responsiveness to customer needs. However, they also require ongoing efforts to identify and eliminate waste, and may not be suitable for all types of businesses. Companies considering implementing a lean supply chain should carefully weigh the potential advantages and disadvantages before making a decision.