Supply chain management is the process of planning, coordinating, and controlling the flow of goods, services, and information from raw material suppliers through to the end customer. It involves managing the entire lifecycle of a product, from sourcing raw materials and manufacturing to distributing and delivering the finished product to customers. In the case of Coca-Cola, supply chain management is a critical aspect of the company's operations, as it plays a key role in ensuring the consistent availability and quality of its products around the world.

Coca-Cola has a complex global supply chain that spans over 200 countries. The company sources raw materials, such as sugar, corn, and other ingredients, from around the world and uses a network of contract manufacturers to produce its finished products. It then distributes these products through a variety of channels, including retail stores, vending machines, and food service outlets.

To manage this complex supply chain, Coca-Cola has implemented a number of strategies and initiatives. One key aspect of these efforts is the company's focus on sustainability. Coca-Cola has set ambitious sustainability goals, including reducing its carbon footprint and water usage, and has implemented a number of initiatives to achieve these goals. For example, the company has invested in renewable energy sources and has implemented water conservation measures at its manufacturing facilities.

Another key aspect of Coca-Cola's supply chain management is its focus on efficiency and cost-effectiveness. The company has implemented a number of initiatives to streamline its operations and reduce waste, including using lean manufacturing techniques and implementing digital technologies, such as blockchain and artificial intelligence, to improve supply chain visibility and efficiency.

In addition, Coca-Cola has a strong focus on quality control and risk management in its supply chain. The company has implemented a number of measures to ensure the quality and safety of its products, including implementing robust quality control processes at its manufacturing facilities and conducting regular audits to ensure compliance with industry standards.

Overall, Coca-Cola's supply chain management is a critical aspect of the company's operations, and is key to ensuring the consistent availability and quality of its products around the world. By focusing on sustainability, efficiency, cost-effectiveness, and quality control, Coca-Cola is able to successfully manage its complex global supply chain and deliver high-quality products to customers.

Supply chain management of coca cola company slides

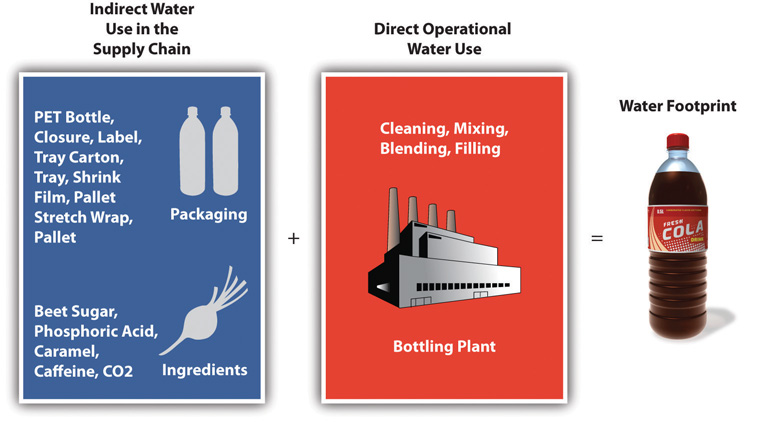

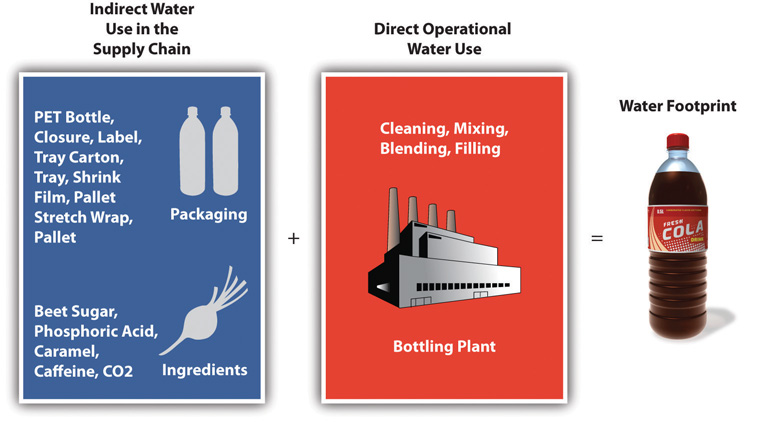

Being the most recognisable beverage brand in the world, with a distinct message and a signature logo, Coca-Cola uses its popularity to push its both traditional and unique beverage flavors. The Coca-Cola formula and brand was bought in 1889 by Asa Griggs Candler December 30, 1851 - March 12, 1929 , who incorporated The Coca- Cola Company in 1892. While the former is used for controlling the quality of the production line within Coca-Cola manufacturing, the latter is concerned with monitoring the entire process of operations, including addressing important problems at high speed. Syrup is made of caramel, phosphoric acid, natural flavoring and caffeine and carbon dioxide for fizz. Since 2010, we have consistently reduced our carbon emissions and water consumption per litre of soft drink produced. These retailer and redistributors deliver stock of Coca-Cola through the country by bulk delivery. At the same time, account managers work with Coca-Cola customers to receive new orders, keep track of the sales cycle, and keep product delivery moving forward.

The Coca

Supply Chain Suppliers At the present moment, Coca-Cola beverages are produced in more than two hundred countries worldwide, which implies that the company has taken care to establish an effective supply chain system to ensure smooth production and distribution. In 2021, we achieved 80% certification of agricultural ingredients on average across all CCH related crops under the Coca-Cola System framework of the Principles for Sustainable Agriculture PSA and we are working towards 100% certification by 2025. In our own business, we are promoting a 100% quality culture with zero tolerance for failure to meet standards. Over 146,000 employees around the world More than 3500 kinds of beverages Sponsorship: Olympics, FIFA, EURO etc. Coca Cola began as a small organization with a limited supply chain in a small local market. Pemberton sold his business to Atlanta businessman, Asa G. Its current president and CEO is MuhtarKent.

Supply Chain

Supplier and Customer Alliances Coca Cola along with many other companies found itself in fierce global competition. The Coca-Cola formula and brand was bought in 1889 by Asa Candler who incorporated The Coca-Cola Company in 1892. Major operation hubs are located in the United Kingdom, Belgium, France, the Netherlands, Luxembourg, Sweden, and Norway Sapardanis, no date. The most important ingredients, such as water and sugar, are sourced locally, and only the type of sugar used can be chosen by the partners. The company operates a franchised distribution system dating from 1889 where The Coca-Cola Company only produces syrup concentrate which is then sold to various bottlers throughout the world who hold an exclusive territory. We have re-stated our zero tolerance for failure to meet standards and deployed a maturity continuum measurement, with stringent processes in place to minimise the occurrence of quality issues.