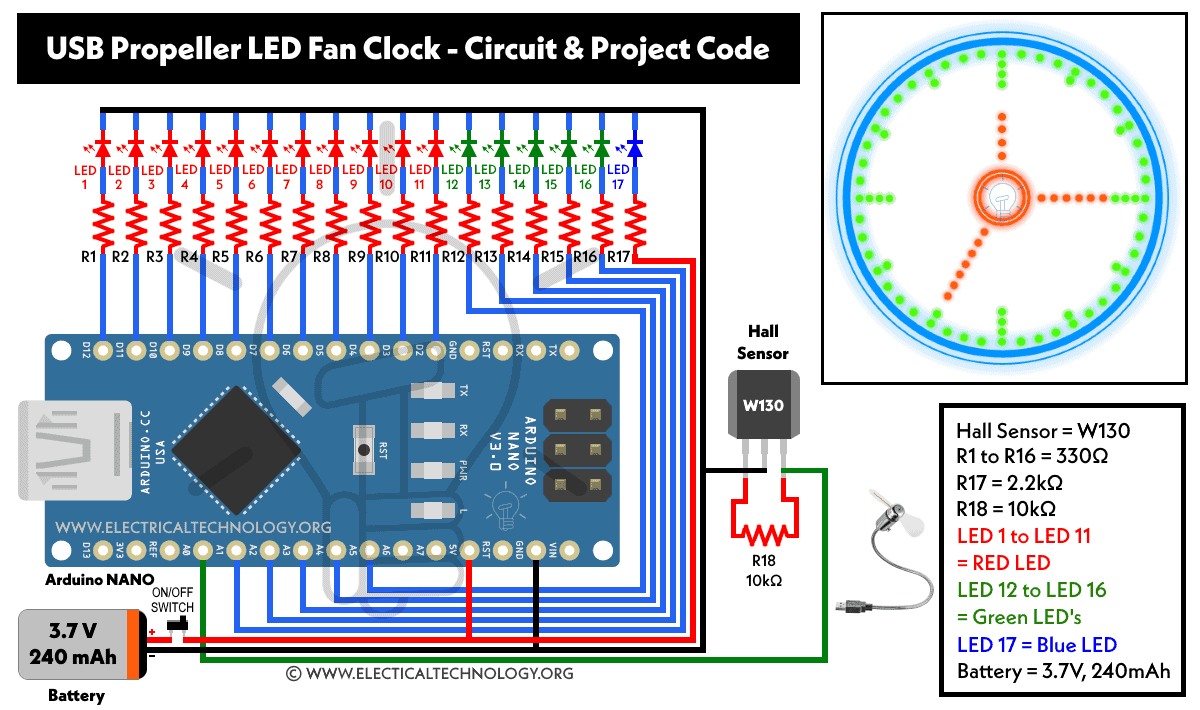

A propeller clock is a unique and visually striking timekeeping device that uses a spinning propeller to display the time. This project involves designing and building a clock that utilizes a small motor and a series of gears to rotate a propeller at a consistent speed. The propeller is marked with numerals or other indicators that allow the observer to read the time as the propeller spins.

The first step in creating a propeller clock is to design the propeller itself. The propeller should be large enough to be easily readable from a distance, and it should be marked with clear and distinct indicators for the hours, minutes, and seconds. The markings should be evenly spaced around the circumference of the propeller, and they should be positioned so that they are easily visible as the propeller spins.

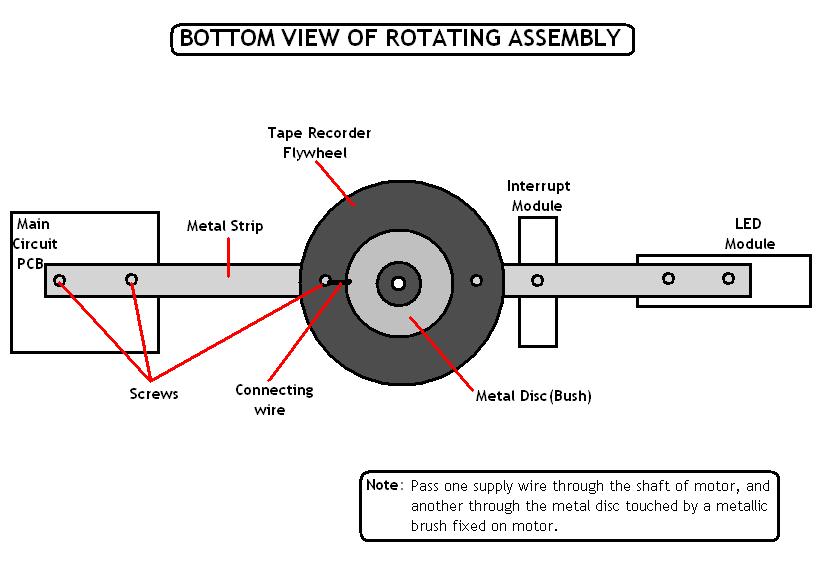

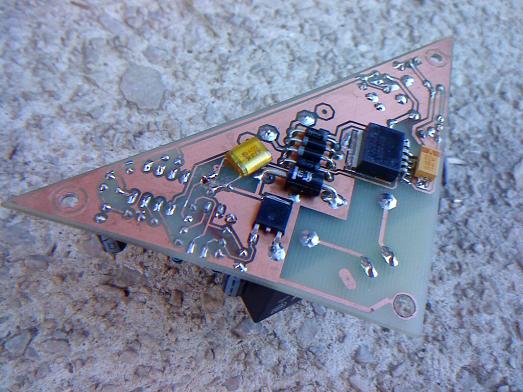

Next, the motor and gears must be selected and assembled. The motor should be powerful enough to rotate the propeller at a consistent speed, but it should not be so powerful as to cause the clock to vibrate or make excessive noise. The gears should be chosen based on the size of the propeller and the desired speed of rotation. The gears should be carefully aligned and secured to ensure that they function smoothly and accurately.

Once the propeller and the mechanical components have been assembled, the clock can be placed in a suitable enclosure. This could be a wooden or metal frame, or it could be a more decorative case made from glass or plastic. The enclosure should be large enough to accommodate the propeller and the mechanical components, and it should be sturdy enough to support the weight of the clock.

Finally, the clock must be tested and calibrated to ensure that it is functioning properly. The propeller should rotate smoothly and consistently, and the markings should be clear and easy to read. Any adjustments or repairs that are needed should be made at this stage to ensure that the clock is accurate and reliable.

Overall, building a propeller clock is a challenging but rewarding project that requires a combination of mechanical skill, attention to detail, and artistic flair. With careful planning and execution, it is possible to create a unique and visually striking timekeeping device that will be a source of pride and enjoyment for years to come.