Material handling refers to the movement, storage, and control of materials in a manufacturing or distribution setting. Effective material handling is essential for efficient and safe operations in any industry, as it helps to reduce costs, minimize errors, and prevent accidents. In this essay, we will discuss some important considerations for material handling, including types of material handling equipment, safety measures, and best practices.

There are many different types of material handling equipment that can be used in a manufacturing or distribution setting. These can include conveyor belts, cranes, forklifts, and pallet jacks. Each type of equipment has its own specific uses and advantages, and it is important to choose the right equipment for the task at hand.

Conveyor belts are commonly used to transport materials through a manufacturing or distribution facility. They can be used to move items from one location to another, or to feed materials into a processing machine. Conveyor belts can be made of various materials, such as rubber, plastic, or metal, and can be powered by electricity, hydraulics, or pneumatics.

Cranes are used to lift and move heavy materials, such as steel beams or machinery. They can be mounted on a fixed base, or they can be mobile and mounted on wheels or tracks. Cranes are typically operated by trained personnel, who use a control panel or joystick to maneuver the crane.

Forklifts are used to lift and transport materials, such as pallets of goods or containers. They are equipped with forks that are inserted under the load, and they can be used to move materials horizontally or vertically. Forklifts can be powered by electricity, gasoline, or diesel, and they are usually operated by trained personnel.

Pallet jacks are used to move pallets of materials, such as boxes or containers. They are equipped with a fork that is inserted under the pallet, and they can be used to move materials horizontally. Pallet jacks are typically powered by hydraulics, and they are operated by trained personnel.

Safety is an important consideration in material handling. It is essential to follow proper procedures and use appropriate equipment to prevent accidents and injuries. This may include wearing protective gear, such as hard hats, gloves, and steel-toed boots, and following proper lifting techniques to prevent strains and sprains. It is also important to keep aisles and work areas clear and free of clutter to prevent tripping hazards.

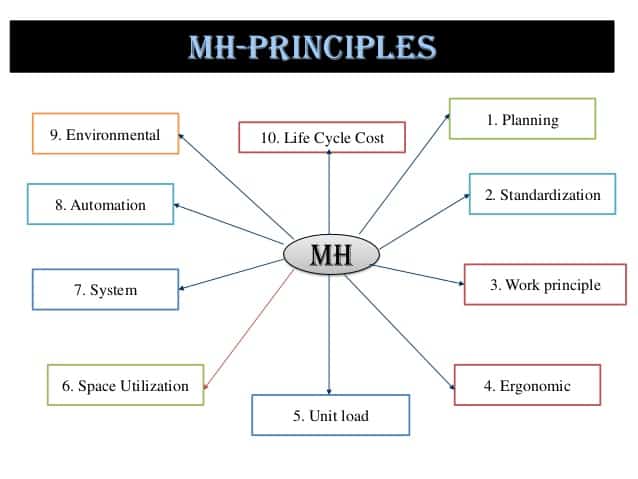

There are also several best practices that can help to improve material handling efficiency and effectiveness. These can include implementing an inventory management system to track materials and ensure that they are available when needed, using standardized containers and pallets to streamline handling, and implementing a material handling plan that outlines the steps for moving and storing materials.

In conclusion, material handling is an essential part of any manufacturing or distribution setting. It is important to choose the right equipment for the task at hand, follow proper safety procedures, and implement best practices to ensure efficient and safe operations.