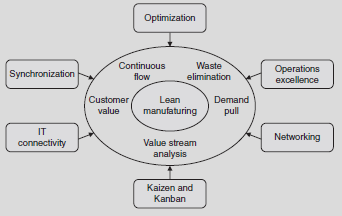

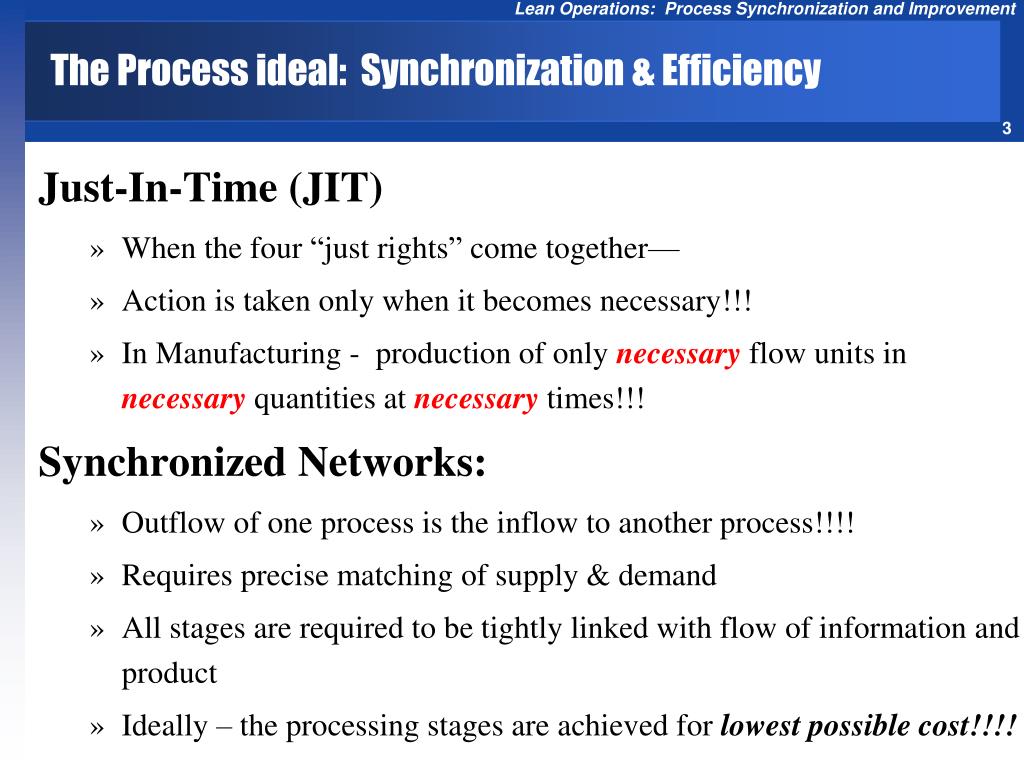

Lean synchronization is a concept that originated in the field of manufacturing and has since been applied to various other industries, including healthcare, software development, and construction. It involves the use of lean principles and techniques to align and coordinate different processes, activities, or teams in order to minimize waste, reduce variability, and improve efficiency and effectiveness.

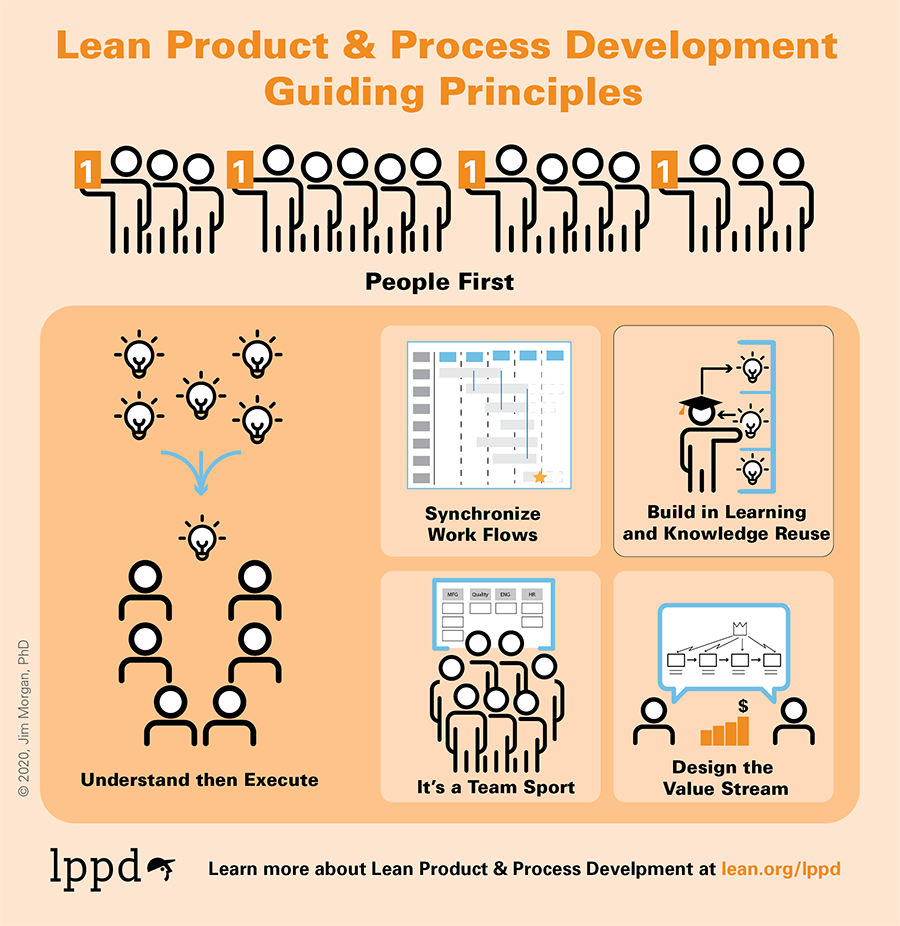

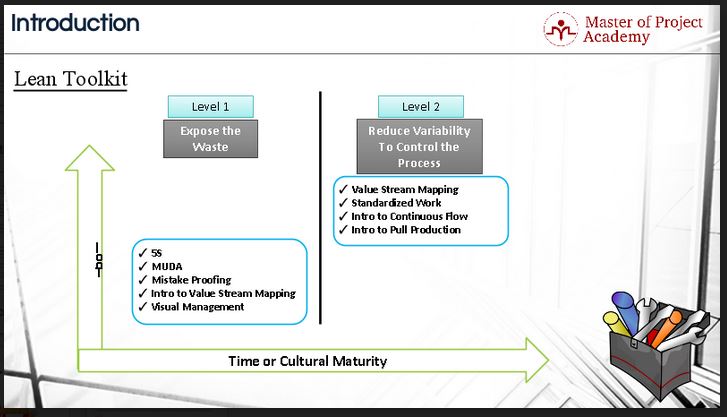

The key principle of lean synchronization is to ensure that work is completed in a smooth and orderly manner, without delays or disruptions. This is achieved through the use of various tools and techniques, such as visual management, pull systems, and standardized work. Visual management, for example, involves using visual aids, such as kanban boards or process flow charts, to clearly communicate information about work tasks, progress, and status. Pull systems, on the other hand, involve allowing work to be initiated and completed only when there is a specific demand or need, rather than producing items in advance or in large batches. Standardized work involves establishing clear and consistent procedures and processes for completing work tasks, which helps to reduce variability and improve efficiency.

Another key aspect of lean synchronization is the focus on continuous improvement. This involves continually reviewing and evaluating processes and identifying ways to eliminate waste, reduce variability, and improve efficiency. This can be done through various methods, such as root cause analysis, value stream mapping, and kaizen events.

Lean synchronization can have a number of benefits for organizations. By aligning and coordinating different processes and activities, it can help to reduce delays and disruptions, improve the flow of work, and increase the overall efficiency of the organization. It can also help to improve communication and collaboration among teams and individuals, as well as increase customer satisfaction by providing a more reliable and consistent service.

In conclusion, lean synchronization is a concept that involves using lean principles and techniques to align and coordinate different processes, activities, or teams in order to minimize waste, reduce variability, and improve efficiency and effectiveness. It can have a number of benefits for organizations, including reducing delays and disruptions, improving the flow of work, and increasing customer satisfaction.