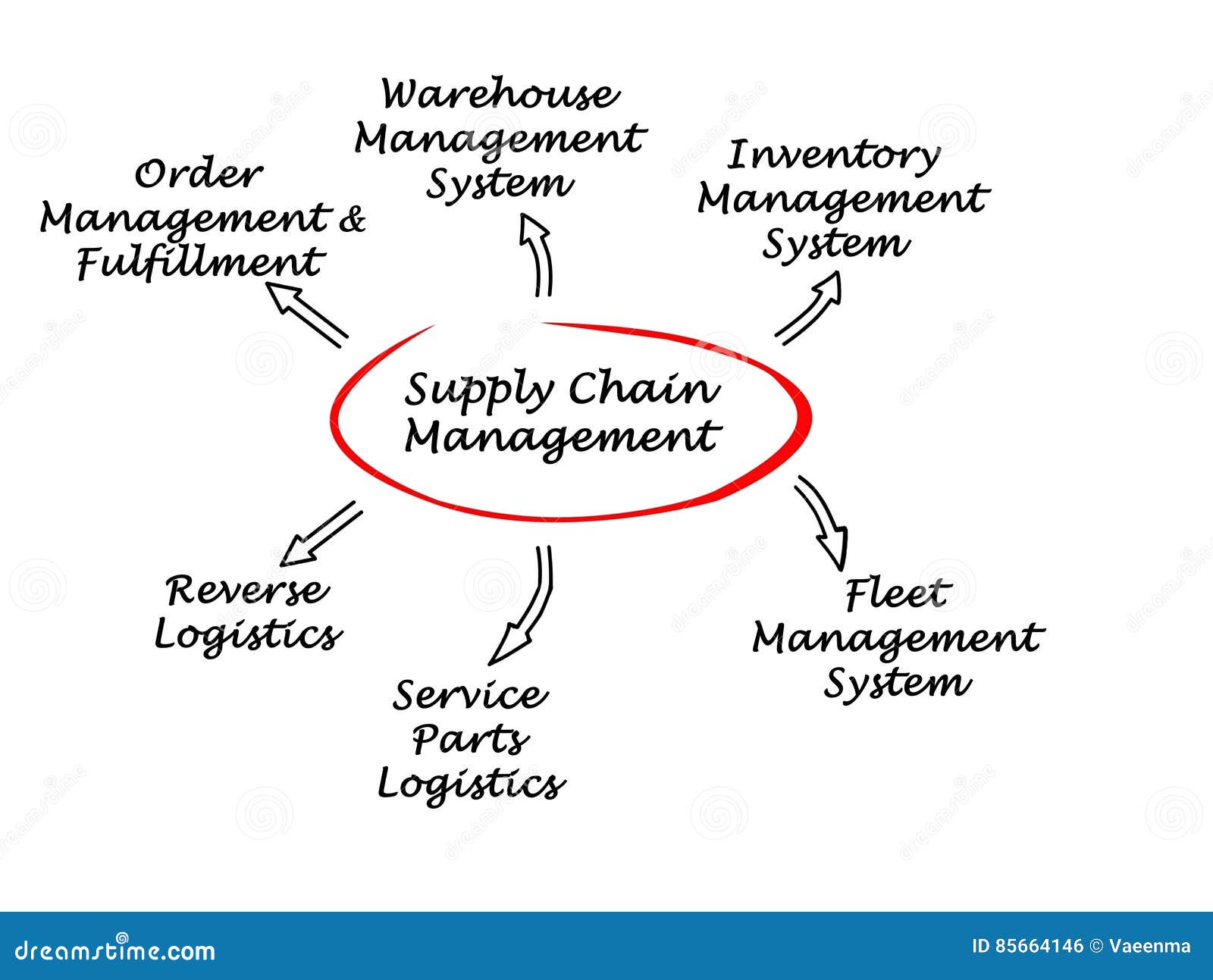

Supply chain management (SCM) refers to the systematic planning, coordination, and control of the flow of goods, services, and information from raw material suppliers to end customers. A well-designed SCM system can help organizations increase efficiency, reduce costs, and improve customer satisfaction. In this essay, we will discuss how to implement a supply chain management system in an organization.

Step 1: Identify the scope of the supply chain

The first step in implementing a SCM system is to identify the scope of the supply chain. This includes identifying the various stakeholders involved in the supply chain, such as suppliers, manufacturers, distributors, and customers. It is also important to identify the various activities that take place within the supply chain, such as sourcing, production, distribution, and delivery.

Step 2: Assess the current supply chain processes

The next step is to assess the current supply chain processes and identify areas for improvement. This may involve analyzing data on inventory levels, delivery times, and customer satisfaction. It may also involve conducting interviews with stakeholders and performing process flow analyses to identify bottlenecks and inefficiencies.

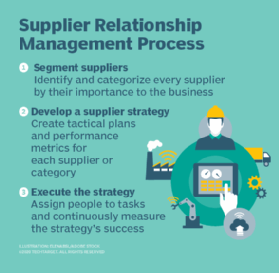

Step 3: Develop a supply chain strategy

Once the current state of the supply chain has been assessed, the next step is to develop a supply chain strategy that aligns with the overall business goals of the organization. This may involve choosing a specific supply chain model, such as a make-to-stock model or a make-to-order model. It may also involve identifying key performance indicators (KPIs) to measure the success of the supply chain.

Step 4: Implement the supply chain management system

After the supply chain strategy has been developed, the next step is to implement the SCM system. This may involve implementing new software or other technologies to support the supply chain processes. It may also involve reorganizing the supply chain to align with the new strategy.

Step 5: Monitor and continuously improve the supply chain

Once the SCM system has been implemented, it is important to continuously monitor and assess its performance. This may involve tracking key performance indicators and identifying areas for improvement. It may also involve adapting the supply chain strategy as needed to meet changing business needs and market conditions.

Implementing a supply chain management system can be a complex process, but it can bring significant benefits to an organization. By increasing efficiency, reducing costs, and improving customer satisfaction, a well-designed SCM system can help organizations achieve a competitive advantage in their industry.