Guideways and slideways are two important components in the design and construction of machine tools and other types of precision machinery. They are used to guide and support the movement of machine components, such as slides, tables, and spindles, and to ensure precise and accurate movement. In this essay, we will explore the different types of guideways and slideways, their functions, and their importance in the operation of machine tools and other precision machinery.

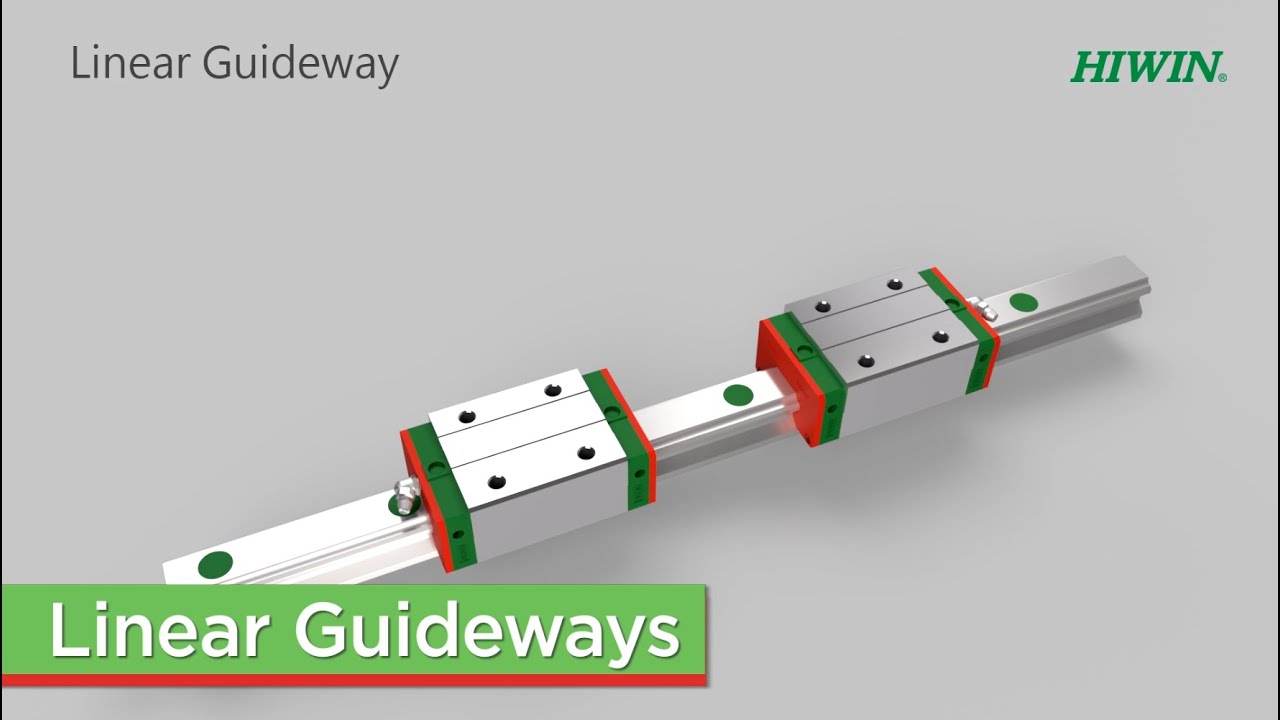

Guideways are surfaces that are used to guide the movement of machine components along a predetermined path. They can be linear or rotary, and they can be either fixed or movable. Linear guideways are used to guide the movement of slides, tables, and other machine components in a straight line, while rotary guideways are used to guide the movement of rotating components, such as spindles and shafts. Fixed guideways are mounted on the machine frame and provide a stable reference for the movement of machine components, while movable guideways can be adjusted or repositioned to accommodate different machining operations.

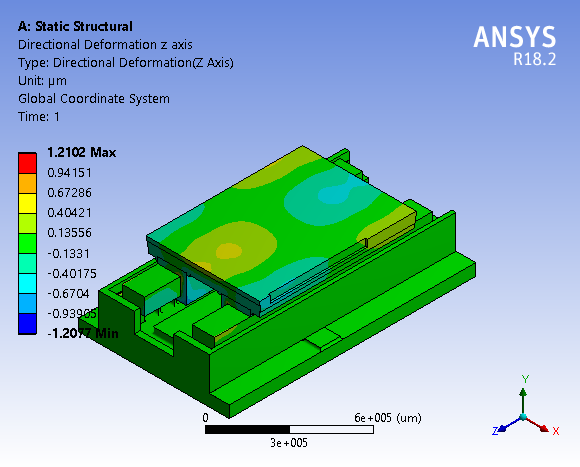

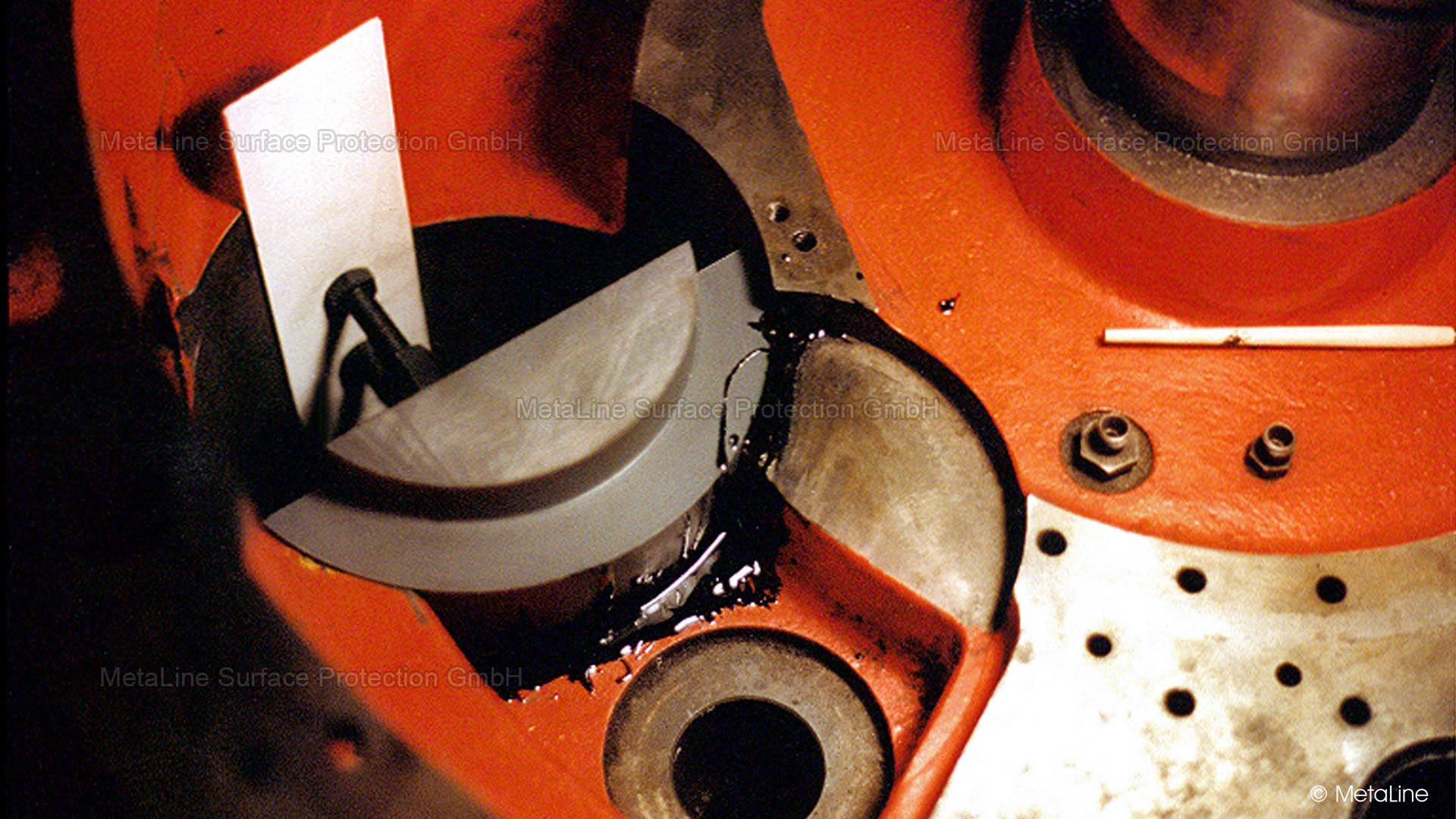

There are several types of guideways, including ball, roller, and hydrostatic guideways. Ball guideways use rows of ball bearings to support and guide the movement of machine components, while roller guideways use cylindrical rollers to provide support and guidance. Hydrostatic guideways use a thin film of oil or another fluid to support and guide the movement of machine components, and they are often used in high-precision applications where precise and consistent movement is critical.

Slideways are surfaces that are used to support and guide the movement of machine components, but they are not as precise as guideways. They are typically used in less demanding applications, such as in the construction of general-purpose machine tools and other types of machinery. Slideways can be linear or rotary, and they can be either fixed or movable. Like guideways, they can be made of various materials, including steel, cast iron, and aluminum.

The importance of guideways and slideways in the operation of machine tools and other precision machinery cannot be overstated. They provide the necessary support and guidance for the movement of machine components, and they ensure that machining operations are precise and accurate. Without them, it would be impossible to achieve the high levels of precision and accuracy that are required in modern manufacturing.

In conclusion, guideways and slideways are essential components in the design and construction of machine tools and other types of precision machinery. They provide the necessary support and guidance for the movement of machine components, and they ensure that machining operations are precise and accurate. They are an integral part of the modern manufacturing process, and their importance cannot be overstated.