The Baja SAE India design competition is an annual event that challenges engineering students to design, build, and race an off-road vehicle. The competition is organized by the Society of Automotive Engineers (SAE) and takes place at various locations across India.

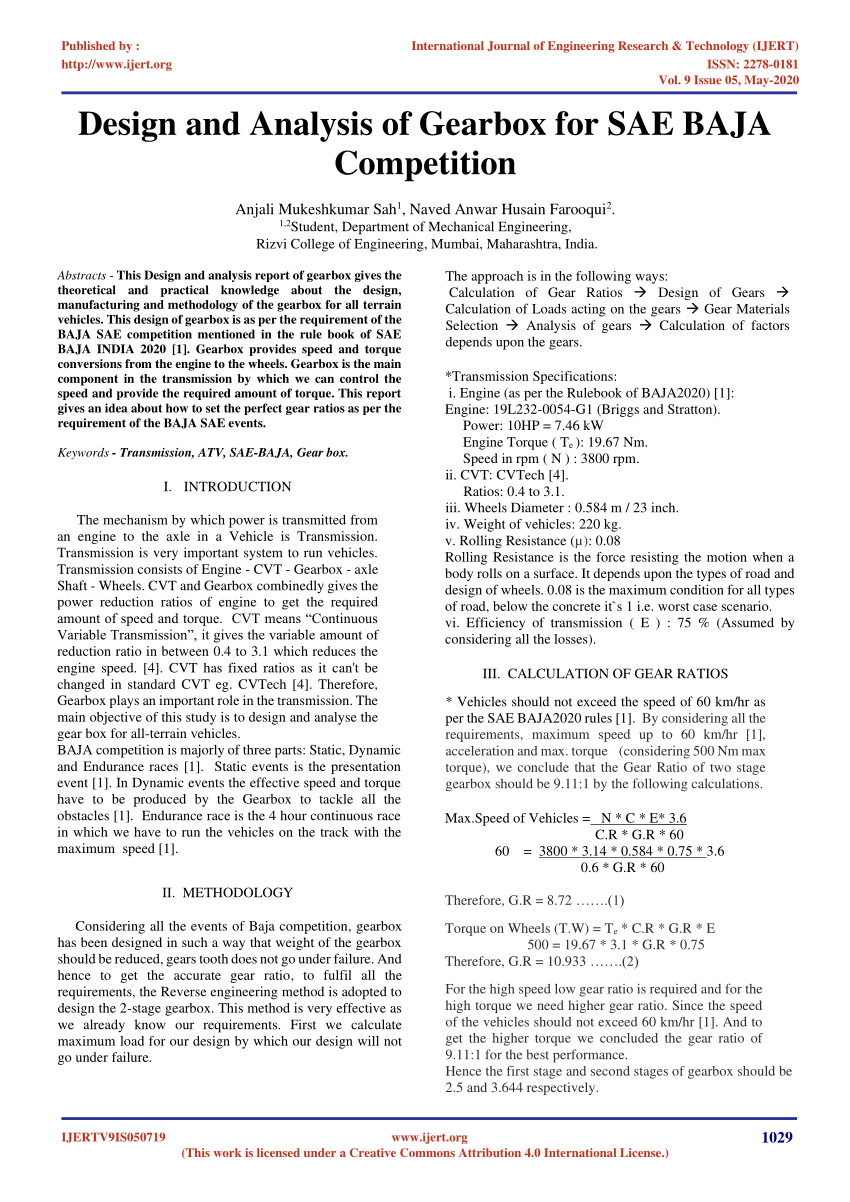

The goal of the competition is to provide students with a real-world engineering experience that simulates the product development process. Teams are required to design a prototype vehicle that meets a set of performance, cost, and safety requirements. They must also present a detailed design report outlining the design and analysis of their vehicle.

The Baja SAE India design competition is a highly competitive event that attracts some of the best and brightest engineering students from across the country. It is an opportunity for students to showcase their skills, learn from their peers, and make a name for themselves in the engineering community.

The design process for a Baja SAE India vehicle is complex and multifaceted. Teams must consider factors such as vehicle weight, power-to-weight ratio, suspension design, and braking performance. They must also ensure that their vehicle meets safety standards and is cost-effective to produce.

To design a successful vehicle, teams must conduct extensive research and analysis. This may include computer-aided design (CAD) simulations, testing prototypes, and gathering data from track tests. Teams must also work closely with sponsors and industry partners to ensure that their vehicle meets the necessary performance and cost requirements.

The design report is a critical component of the Baja SAE India competition. It is a comprehensive document that outlines the design and analysis of the team's vehicle. The report should include information on the vehicle's design, manufacturing processes, and testing results. It should also include a financial analysis of the project, including an estimate of the total cost to produce the vehicle.

In conclusion, the Baja SAE India design competition is a challenging and rewarding event that provides engineering students with a unique opportunity to apply their skills in a real-world setting. The design report is an important part of the competition, as it documents the team's work and demonstrates their understanding of the design process.